Dam and River Water Treatment

The Problem with Colloids in Water

Undissolved impurities are very fine clay or organic vegetation material which colours the water and remain in suspension without settling out. Water by definition is a clear, colourless, tasteless and odourless liquid. Good quality water is also bound by that definition and is vital for our health and is a major component in maintaining a quality of life. Water is the best solvent known to man. Water generally comes to use as rain, or from underground streams. Water contacts and dissolves many minerals and natural organic compounds.

Untreated Water

If left untreated, such material, now perhaps a part of your water supply, becomes a major problem for your health and other economic reasons. Impurities can cause scale, corrosion, odours, discolouration affecting life, lifestyle, health, equipment operation, food production and agriculture, to name a few. Microbilogical activity or simply, bacteria, parasites, is another distinct issue.

Undissolved impurities are very fine clay or organic vegetation material which colours the water and remain in suspension without settling out.

Particles that do not settle, impurities that remain in suspension, solids, and other matter need to be removed to make the water usable.

Flocculants

World Health Organisational Potable Water Drinking Guidelines

Guidelines are set for drinking water in Australia and standards are also applied to other water used for other purposes. The aim is to bring this water, as cost effectively as possible, to those standards or the standard needed for use.

The water supply needs to meet the physical, mineral and microbiological levels set, or better. Quite often, better or higher quality water is needed for a variety of reasons.

Many people think that undissolved impurities can be removed by a simple physical filtration process. Filters as a primary means of removal are often quite ineffectual or block up very quickly.

On filtering suspended clay particles from channel water, someone said that is was like trying to strain the sugar out of tea. Without a process of disinfection, filters can also become seed bed for bacteria for bacteria contamination, particularly carbon.

How to Meet These Standards

Collodial Matter (In Suspension) in Water.

- A colloid is matter that is so small and has such little weight that it literally floats indefinitely.

- Clay particles are the most common and the Murray River water supply has that problem.

- Most dams, unless with very clear water, are likely to have colloidal matter.

- Iron in water that also has a bacteria presence can create this issue.

- Cooling tower water comes into this category. It can collect quite a lot of impurities very quickly. Bacteria will embed into these colloids and be difficult to penetrate effectively with biocides.

- Grey water is very similar and just a successfully treated quite simply back to clean drinking water.

- Colour of untreated water

The colour of these bodies of water and the collection of this suspended matter places it into a situation where it is rendered unsuitable for use and dumping is usually called for, or slug disinfection to overcome the bacteria contamination.

Both of these solutions are costly and often not permitted. Flocculants are a highly efficient manner of dealing with this problem.

What Are Flocculants?

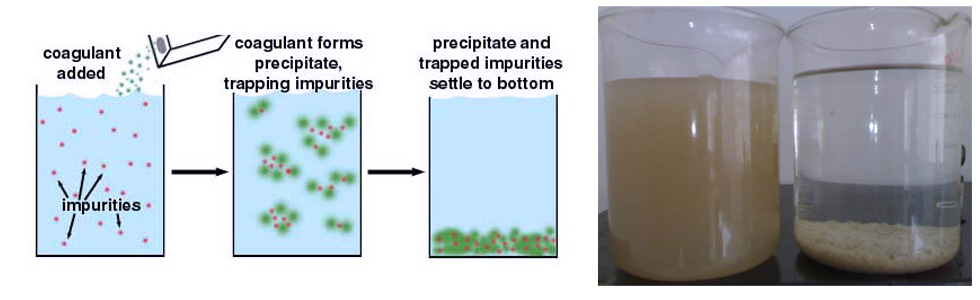

Flocculants are derived from chemicals that place a charge factor on each floating particle cause them to gather together and clump develop greater weight and eventually fall by gravity. These chemicals are anionic and catonic or have negative and positive charges or a mix. These are based on polymers and coagulants.

These chemicals are tested against the water to be treated to determine that which is required. The end results must achieve high quality clear water.

Grey

Water

Black

Water

Industry

Waste

Winery

Waste

Tannin

Affected Water

Removing High Iron Levels With Tank Treatment

Algae in

Stored Water

Toxic

Elements

What Effective Flocculants can Use Successfully Treat?

So How do We Deal with This Problem?

We use this advanced polymer/coagulation technology. It involves top-end water chemistry and a good working knowledge of it. Knowledge of micro-biology is also an asset. We use pH control when necessary in order for the appropriate chemical to activate within a particular pH boundary and effectively treat the problem.

The treatment system targets the fine matter to be attracted to the polymer-coagulant and then it gathers weight and falls out as a “pinfloc”. This method is so effective that it will drop 97 % of all matter out of the solution, including the majority of bacteria, but not necessarily minerals such as hardness minerals.

How it Works

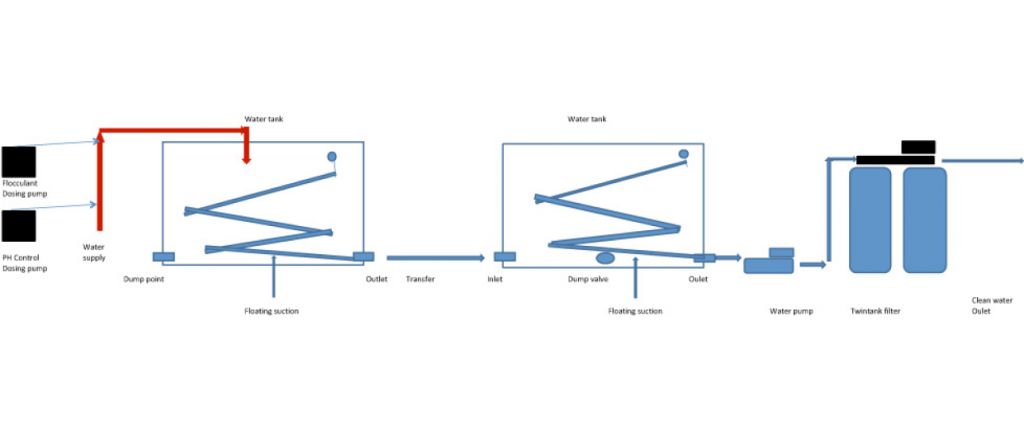

When needed, the pH dosing pump injects a suitable pH buffer into the pipeline. This increases the pH of the water to be treated to a level where the polymer, coagulant or mix will work effectively.

The polymer is dosed accurately by injection and flows through the manifold system, where agitation starts, and the mix flows into the tank into the center-drop tube, and sprays out above the tank floor of this tube where effective coagulation takes place in a treatment tank sized and suitable for settlement.

The clay or colloid particles begin to floc and fall by gravity and remain at the bottom of the treatment tank.

Calculations

When it is calculated properly, the clay, or affected colloid particles will drop out quite quickly. Your clean product water rises to the top of the treatment tank often within the 5 NTU turbidity range as required by the EPA without recourse to filtration at this point.

Calculation of the amount of flocculant needed is based on pH control (if required), influent flow rates and ppm of treatment required.

This information, flow rate of the water, ppm required, etc, is now pre-set into computerized dosing pumps and controlled by a pulse head water meter. A separate pH dosing pump and control is often also needed.

Clean Water Transferred to Another Tank

The clean water flows down a pick-up tube that floats about 400-600mm below the clean water level and gravitates down the outlet to a second treatment tank of similar height as the secondary settling tank and the same scenario of gravity suction is employed to produce the clean water for recovery, re-use and further treatment as needed for each intended use.

It is then pumped for use. The treated quality is very high.

Test the residue for suitability as a fertiliser base.

A second outlet can be fitted where the residue can be drained off periodically, or

Utilise the tank-cleaning people, possibly every two years, or as required to pump out the sludge/sediment left behind, which is typically 1-5% of the influent treated water.

Some deploy enzymes to anaerobically break down the mass further to a harmless liquid.

Residue Removal

You have choices here but is dependant on source water and use.

For pre-disinfection, a finer filter system to 5 micron absolute is often essential.

Equipment Required

- Pulse head flow meter

Chemical dosing pumps (We prefer a range of computerized chemical dosing pumps for cost, performance and reliability and a known, low-cost service level.) - PH control if required, pH probe in pH dosing is required as is the appropriate dose pump.

- Mixing manifold and support board

- Float switch, valve and 240v-24v power pack.

- Polymer, flocculant, coagulant, mix

- Tanks conversion

- Chemical

- Dosing pump maintenance (annual seal replacements-inexpensive)

- Seasonal polymer testing for changes in effluent requirement and we usually teach your staff this and set up the testing charts.

- Potassium Hydroxide @48% for pH control, very low-cost.

- Filtration, if manual filter cartridges, or automatic, higher initial costs but much lower maintenance.

How to Meet These Standards

These are as follows.

Summary

This treatment method produces consistently high-grade water with extremely low maintenance, and low operating costs. It is the only method available for cost-effectively treating any type of water quality problem being colloid based in all water supplies.

To obtain a quote please send us:

- Water analyses turbidity report

- Water volume requirement per a day or an hour.

If you don’t have any of the information above we can visit the site and perform all the necessary tests.